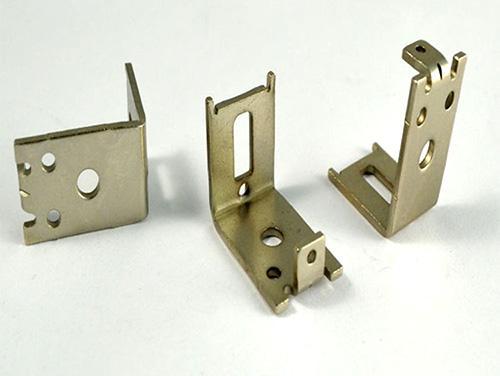

Stamping

Material:

The materials for stamping parts are mainly switch shrapnel, hot-rolled or cold-rolled (mainly cold-rolled), and copper strip metal strip materials, such as copper and copper alloy sheets, contact sheets, shrapnel, carbon steel sheets, alloy steel sheets, springs Steel plates, galvanized plates, tin plates, stainless steel plates, aluminum and aluminum alloy plates, etc. The processing of stamping parts includes blanking, bending, deep drawing, forming, finishing and other processes.

application:

Used in all kinds of electronic appliances, thermostats, relays, protectors, circuit breakers, household switches, automotive panel switches, light switches, home appliances, etc.;

advantage:

Compared with castings and forgings, stamping parts are thin, uniform, light and strong. Stamping can produce workpieces with ribs, ribs, undulations or flanging that are difficult to manufacture by other methods to improve their rigidity. Due to the use of precision molds, the accuracy of the workpiece can reach micron level, and the repeatability is high and the specifications are consistent, and holes, bosses, etc. can be punched out.

Cold stampings are generally no longer machined, or require only a small amount of machining. The accuracy and surface state of hot stamping parts are lower than those of cold stamping parts, but they are still better than castings and forgings, and the amount of machining is less.

Capacity:

30 million pieces/month;