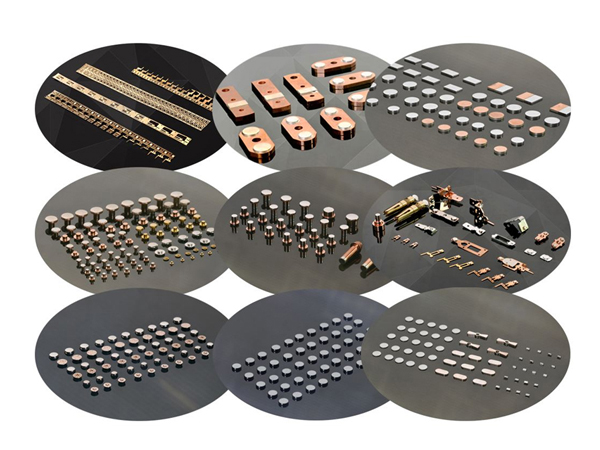

In-mold riveted parts

Material:

Terminals/shrapnel: red copper, brass, phosphor bronze, beryllium copper, cupronickel, copper-nickel, iron, aluminum, stainless steel, Monel alloy, metal composite tape (self-made), etc.;

Contact: Surface material: sterling silver, silver nickel, silver copper, silver cadmium oxide, silver tin oxide, silver tin indium oxide, etc., the wire is self-made or imported;

Base material: red copper, copper-nickel, etc.;

Specification Type:

Stamping + wire feeding and riveting + detection: single wire or double wire can be sent (wires are divided into round wire and square wire), single-sided or double-sided riveting and other riveting methods, which are used for single metal contacts;

Stamping + sending contact riveting + detection: single (double) contact riveting method, composite metal contact adopts this method;

application:

For thermostats, relays, protectors, circuit breakers, household switches, car panel switches, light switches, etc.;

advantage:

Through the improvement of the mold, the riveting action is realized in the mold, the tapping in the mold is increased, and the optical fiber induction detection of riveting leakage is added to realize automation. The mold life can reach 5KK times, and the speed can reach more than 100 times per minute, which greatly saves labor costs. Compared with traditional manual riveting, it has fast speed, high precision and stable quality;

Capacity:

30 million pieces/month;